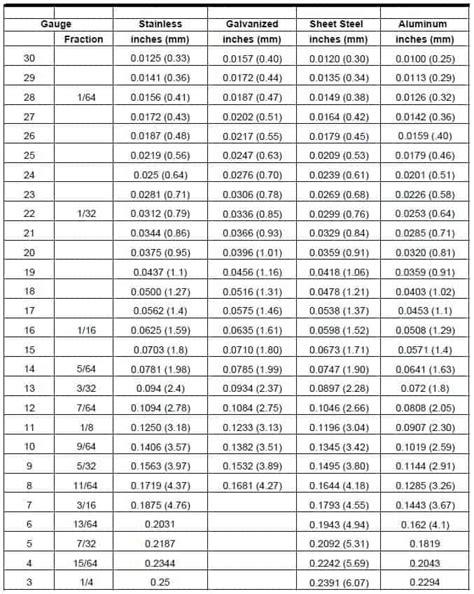

aluminium sheet metal gauge thickness Use our handy chart to convert standard gauge numbers in decimals of an inch for sheet steel, aluminum and stainless steel. Need to bend sheet metal? It's really easy to build a simple DIY metal brake!!TOOLS & SUPPLIES:https://kit.co/iliketomakestuff/my-metalworking-toolshttps://k.

0 · sheetmetal gauge table in mm

1 · sheet metal thickness chart printable

2 · sheet metal gauge chart galvanized

3 · sheet metal dimension chart

4 · gauge to mm chart pdf

5 · aluminum sheet metal size chart

6 · aluminum sheet gauge size chart

7 · aluminum gauge thickness chart printable

How to Build a Soundproof Generator Box (Quiet Portable DIY Enclosure) Read full guide here: https://www.soundproofable.com/soundp. When you have power outages or need lighting for outdoor.

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . Ga. is different from inches, there is no conversion formula. Even when the non . The following sheet metal gauge size reference chart gives the weight and thickness .

Use our handy chart to convert standard gauge numbers in decimals of an inch for sheet steel, aluminum and stainless steel.A sheet metal gauge or gage indicates the standard sheet metal thickness for a specified material. For example, CRCA gauge number 11 is 3 mm thickness, whereas for aluminum 11 gauge is .Quick Tips on How to Use the Aluminum Gauge Chart: Identify Your Needs: Determine the required thickness for your project before referring to the chart. Match Specifications: Use the . The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 .

A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting .Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to .The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .Use our handy chart to convert standard gauge numbers in decimals of an inch for sheet steel, aluminum and stainless steel.

For example, in one gauge system, 18 gauge steel measures 0.0478 inches thick, but 18 gauge aluminum is 0.0403 inches thick. Because of the varying thicknesses, a gauge chart should be used to ensure the metal meets the required dimensions.A sheet metal gauge or gage indicates the standard sheet metal thickness for a specified material. For example, CRCA gauge number 11 is 3 mm thickness, whereas for aluminum 11 gauge is 2.23 mm. What is the thickest and thinnest gauge of sheet metal?Quick Tips on How to Use the Aluminum Gauge Chart: Identify Your Needs: Determine the required thickness for your project before referring to the chart. Match Specifications: Use the chart to find the exact gauge that corresponds to the desired aluminum thickness. The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 inches thick if made from stainless steel. That’s why it is important to ensure you use the right conversion chart for the given piece of sheet metal.

sheetmetal gauge table in mm

A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical part of the sheet metal fabrication design processBelow is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .

Use our handy chart to convert standard gauge numbers in decimals of an inch for sheet steel, aluminum and stainless steel.

For example, in one gauge system, 18 gauge steel measures 0.0478 inches thick, but 18 gauge aluminum is 0.0403 inches thick. Because of the varying thicknesses, a gauge chart should be used to ensure the metal meets the required dimensions.A sheet metal gauge or gage indicates the standard sheet metal thickness for a specified material. For example, CRCA gauge number 11 is 3 mm thickness, whereas for aluminum 11 gauge is 2.23 mm. What is the thickest and thinnest gauge of sheet metal?

Quick Tips on How to Use the Aluminum Gauge Chart: Identify Your Needs: Determine the required thickness for your project before referring to the chart. Match Specifications: Use the chart to find the exact gauge that corresponds to the desired aluminum thickness. The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 inches thick if made from stainless steel. That’s why it is important to ensure you use the right conversion chart for the given piece of sheet metal.

A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical part of the sheet metal fabrication design process

scrap box beam steel

sheet metal thickness chart printable

Lighted chrome frame sliding door with switch and spare outlet. Steel body, 2 fixed shelves, surface mount. 23-1/2 in W x 18-1/4 in H x 5-1/2 in D. Try Curbside, 10% OFF!

aluminium sheet metal gauge thickness|sheet metal dimension chart