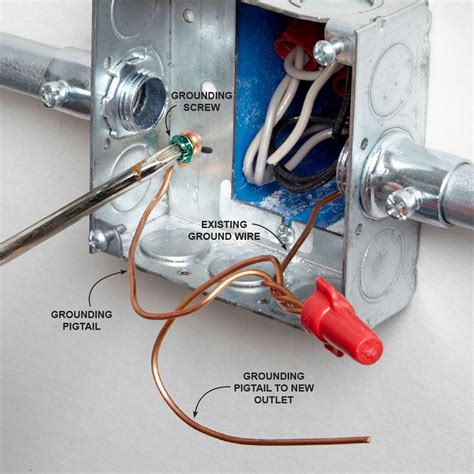

can ground wire be screwed to metal subpanel box If you want to ground a box, the ground wire must have 6" of free length in the box, just like any other wire you might splice here. Since it's stranded wire, that is a royal PITA to put on a screw (it tends to birdcage when you . When it comes to choosing the right gauge steel for floor pans, there are a few options to consider. The most commonly recommended gauges seem to be 16, 18, and 20. The choice of gauge depends on factors such as the intended .

0 · wire to metal box without ground

1 · wire for ground box

2 · how to attach wire to ground box

3 · grounding wires for subpanels

4 · grounding wire for metal box

5 · grounding in subpanel

6 · grounding for subpanel pipe

7 · bonding screw for sub panel

Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage.

However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom . If you want to ground a box, the ground wire must have 6" of free length in the box, just like any other wire you might splice here. Since it's stranded wire, that is a royal PITA to put on a screw (it tends to birdcage when you .

Mechanically securing a terminal bar (as you say, the ground bus bar) to the subpanel metal enclosure provides terminals to "land" the branch circuit ground wires, whether . If there is no second ground source available for the sub-panel, then a ground wire may be run from the Main Panel to the Sub Panel and used as a second source of grounding. If the Sub Panel is in the same building as the . In the older versions of the code, you could just tie the ground wires around a screw in the box, such as the 8-32 that is commonly inside boxes to tighten down as a romex clamp. Now you need to use a Green Grounding .Is it grounded by being screwed to the subpanel? I have 2 ground bar options, one one has a lug for a larger grounding wire and the other is just designed for the ground wires coming from the .

To summarize everything, we need to keep subpanel grounding and neutral isolated to maintain the correct flow of current from the subpanel to the main panel and prevent short circuits and ground faults from harming our .

The sub panel has no equipment ground connected directly to the main panel. It does have two ground rods installed. The neutral is floating on its own neutral bar. However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground.

If you want to ground a box, the ground wire must have 6" of free length in the box, just like any other wire you might splice here. Since it's stranded wire, that is a royal PITA to put on a screw (it tends to birdcage when you tighten the .

Mechanically securing a terminal bar (as you say, the ground bus bar) to the subpanel metal enclosure provides terminals to "land" the branch circuit ground wires, whether green, bare or other color (except white or gray). The ground terminal bar is usually available in a bag with mounting screws and labels.

If there is no second ground source available for the sub-panel, then a ground wire may be run from the Main Panel to the Sub Panel and used as a second source of grounding. If the Sub Panel is in the same building as the Main Panel, then a grounding rod isn't required. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches.

In the older versions of the code, you could just tie the ground wires around a screw in the box, such as the 8-32 that is commonly inside boxes to tighten down as a romex clamp. Now you need to use a Green Grounding screw that is .Is it grounded by being screwed to the subpanel? I have 2 ground bar options, one one has a lug for a larger grounding wire and the other is just designed for the ground wires coming from the circuits. . Does the ground wire being fed from my meter main to this ground lug provide grounding to the metal of the subpanel box or would I connect .

To summarize everything, we need to keep subpanel grounding and neutral isolated to maintain the correct flow of current from the subpanel to the main panel and prevent short circuits and ground faults from harming our electrical system and appliances. The Code only reinforces this practice. The sub panel has no equipment ground connected directly to the main panel. It does have two ground rods installed. The neutral is floating on its own neutral bar.

7. Wire main, neutral, and equipment ground. Refer to rating label inside equipment for proper tightening torque. Wire neutral and equipment ground only in direction indicated by arrows. If required, ground and bond neutral to box using screw provided. However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground. If you want to ground a box, the ground wire must have 6" of free length in the box, just like any other wire you might splice here. Since it's stranded wire, that is a royal PITA to put on a screw (it tends to birdcage when you tighten the .

Mechanically securing a terminal bar (as you say, the ground bus bar) to the subpanel metal enclosure provides terminals to "land" the branch circuit ground wires, whether green, bare or other color (except white or gray). The ground terminal bar is usually available in a bag with mounting screws and labels.

If there is no second ground source available for the sub-panel, then a ground wire may be run from the Main Panel to the Sub Panel and used as a second source of grounding. If the Sub Panel is in the same building as the Main Panel, then a grounding rod isn't required. You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches.

In the older versions of the code, you could just tie the ground wires around a screw in the box, such as the 8-32 that is commonly inside boxes to tighten down as a romex clamp. Now you need to use a Green Grounding screw that is .Is it grounded by being screwed to the subpanel? I have 2 ground bar options, one one has a lug for a larger grounding wire and the other is just designed for the ground wires coming from the circuits. . Does the ground wire being fed from my meter main to this ground lug provide grounding to the metal of the subpanel box or would I connect .

To summarize everything, we need to keep subpanel grounding and neutral isolated to maintain the correct flow of current from the subpanel to the main panel and prevent short circuits and ground faults from harming our electrical system and appliances. The Code only reinforces this practice. The sub panel has no equipment ground connected directly to the main panel. It does have two ground rods installed. The neutral is floating on its own neutral bar.

wire to metal box without ground

wire for ground box

Roof and building specifications often use “gauge” when stating the required material thickness. A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof.

can ground wire be screwed to metal subpanel box|wire for ground box