cnc insert for cnc machines CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting . 29.87-in range hood in stainless steel allows you to close the hood when not in use, providing an integrated, flush look with cabinetry. 300-CFM integrated blower effectively removes heat, odor, grease and smoke from your cooktop. 3-speed slider control accommodates your cooking needs

0 · types of inserts in cnc

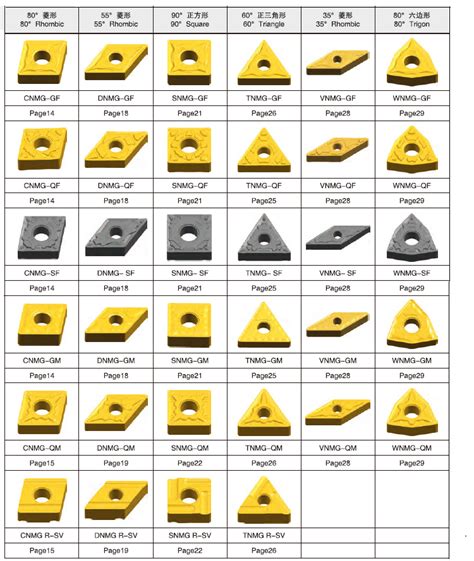

1 · strongest shape of carbide insert

2 · cnc lathe insert chart

3 · cnc inserts and tooling

4 · cnc insert types pdf

5 · cnc insert pdf

6 · cnc insert chart

7 · best carbide insert for metalworking

Under-cabinet coffee makers are perfect for small kitchens, apartments, or offices because of their sleek design and compact size. They are also ideal for people who prefer to have their coffee maker at eye level and easily accessible. The programmable features of under-cabinet coffee makers are another fantastic benefit.3 in 1 Under the Cabinet Electric Can Opener, Blade Sharpener, Bottle Opener, Under The Counter Mount, For Large And Small Cans (Black)

Choosing the right cutting insert is crucial for optimal CNC machining performance. Cutting inserts, despite their small size, have a huge impact on the quality of the final product, machining speed, and tool life. CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .Choosing the right cutting insert is crucial for optimal CNC machining performance. Cutting inserts, despite their small size, have a huge impact on the quality of the final product, machining speed, and tool life. CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining efficiency and product quality. This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. .

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency.There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Learn the essential parameters of ISO nomenclature for selecting CNC inserts efficiently. Focus on key factors to streamline insert selection for optimal machining performance. CNC Turning insert shapes and their cutting properties. When we select an insert for an operation, we select it based on these characteristics: – How versatile it is in cutting different part contours – Spindle power required to cut – Vibrations during cutting, which are a result of the extent and direction of cutting forces

In this comprehensive guide, we will dive deep into the world of CNC turning inserts, explore the different types, materials, and coatings available, and provide essential tips on how to choose the right insert for optimal efficiency.CNC turning inserts are replaceable cutting tools designed for removing material during the turning process. They are typically made from carbide, ceramic, or other advanced materials that provide excellent hardness, heat resistance, and wear resistance.Inserts are the replaceable cutting tips used on CNC turning tools, and they play a crucial role in achieving high precision, surface finish, and tool life. In this article, we will explore the various types of inserts used in CNC turning and their specific applications. CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .

Choosing the right cutting insert is crucial for optimal CNC machining performance. Cutting inserts, despite their small size, have a huge impact on the quality of the final product, machining speed, and tool life. CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining efficiency and product quality. This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. .

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency.There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. Learn the essential parameters of ISO nomenclature for selecting CNC inserts efficiently. Focus on key factors to streamline insert selection for optimal machining performance. CNC Turning insert shapes and their cutting properties. When we select an insert for an operation, we select it based on these characteristics: – How versatile it is in cutting different part contours – Spindle power required to cut – Vibrations during cutting, which are a result of the extent and direction of cutting forces

In this comprehensive guide, we will dive deep into the world of CNC turning inserts, explore the different types, materials, and coatings available, and provide essential tips on how to choose the right insert for optimal efficiency.CNC turning inserts are replaceable cutting tools designed for removing material during the turning process. They are typically made from carbide, ceramic, or other advanced materials that provide excellent hardness, heat resistance, and wear resistance.

duct and sheet metal fabrication in mesa az

types of inserts in cnc

strongest shape of carbide insert

cnc lathe insert chart

Oldcastle Infrastructure’s underground pull boxes and handholes are the industry’s leading product choice to protect and provide access to electrical cables and transformers and are a preferred alternative to running electrical power cables above the ground and across utility poles.

cnc insert for cnc machines|best carbide insert for metalworking