cnc laser diamond cutting machine factory Hallmark, 4G is an all-in-one Diamond Processing System that can perform Table Sawing, Crowning, Bruiting, and Cone Blocking with the one-time fixing of the diamond rough. . Roof and building specifications often use “gauge” when stating the required material thickness. A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof.

0 · rough diamond cutting machine

1 · diamond sarin machine price

2 · diamond laser inscription machine

3 · diamond laser cutting machine price

4 · diamond drill core cutting machine

5 · diamond cutting machine price

6 · can a laser cut diamond

7 · automated diamond cutting machine

The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 and must be painted visibly green.

"DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets . The DaVinci Diamond Factory transforms rough diamonds into brilliant cut diamonds with up to 57 facets in a single operation. Polishing processes are reduced to a final .

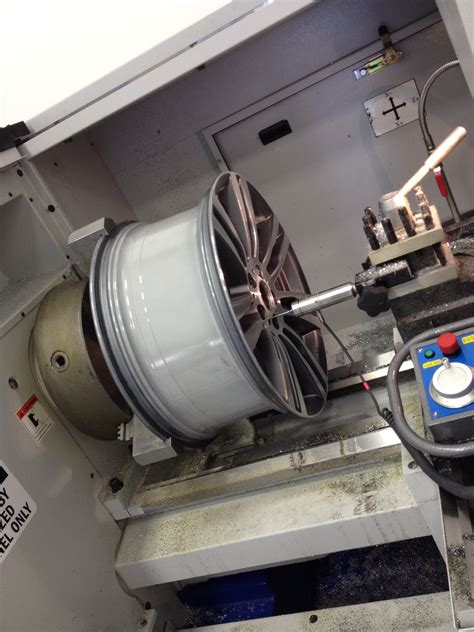

The diamond factory consists of a precision CNC machine with a high power green laser, a compact water pump and an ultra pure water unit. The DaVinci system also includes a cam software that reads the planning files and . Hallmark, 4G is an all-in-one Diamond Processing System that can perform Table Sawing, Crowning, Bruiting, and Cone Blocking with the one-time fixing of the diamond rough. .Ultrashape MK7, Bettonville’s most advance diamond cutting laser machine features OEM CAD/CAM software compatible with majority of CAD formats and Bettonville’s proprietary postprocessor installed on a powerful HP graphic .

It transforms rough diamonds into brilliant cut diamonds in a single fully automated process. In preparation for the laser process, the rough diamond is scanned and planned by an external planning device. Stone parameters are .The LAZER GRN ng uses the green laser, which works on short wavelength and provides fierce power and precision. The accuracy in cutting results into minimum weight loss and lowest possible breakage and hence more yield per cut diamond.Highly Accurate and Long Life X-Y-Z CNC Stages for accurate cutting performance. Automatic 360° Fixture For twin side sawing. Dust Protective Enclosure For optimum life of optical components.For analysis, measurement and modeling of a semi-polished or polished diamonds proportions and dimensions, to laser marking polishing instructions or laser inscribing the ID number on a diamond, Sarine Cut & Symmetry .

"DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets in a single process. The DaVinci system also allows fancy shaping. "DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets in a single process. The DaVinci system also allows fancy shaping.

The DaVinci Diamond Factory transforms rough diamonds into brilliant cut diamonds with up to 57 facets in a single operation. Polishing processes are reduced to a final smoothing step to remove the remaining thin black carbon layer. The diamond factory consists of a precision CNC machine with a high power green laser, a compact water pump and an ultra pure water unit. The DaVinci system also includes a cam software that reads the planning files and defines the facet cutting order for optimum yield.Hallmark, 4G is an all-in-one Diamond Processing System that can perform Table Sawing, Crowning, Bruiting, and Cone Blocking with the one-time fixing of the diamond rough. It is the 4th generation laser processing machine with inbuilt software for laser beam stability & robotic CNC control features.

Ultrashape MK7, Bettonville’s most advance diamond cutting laser machine features OEM CAD/CAM software compatible with majority of CAD formats and Bettonville’s proprietary postprocessor installed on a powerful HP graphic workstation. It transforms rough diamonds into brilliant cut diamonds in a single fully automated process. In preparation for the laser process, the rough diamond is scanned and planned by an external planning device. Stone parameters are then transferred to the DaVinci system.

The LAZER GRN ng uses the green laser, which works on short wavelength and provides fierce power and precision. The accuracy in cutting results into minimum weight loss and lowest possible breakage and hence more yield per cut diamond.Highly Accurate and Long Life X-Y-Z CNC Stages for accurate cutting performance. Automatic 360° Fixture For twin side sawing. Dust Protective Enclosure For optimum life of optical components.For analysis, measurement and modeling of a semi-polished or polished diamonds proportions and dimensions, to laser marking polishing instructions or laser inscribing the ID number on a diamond, Sarine Cut & Symmetry technologies offer a suite of products and solutions that cover the entire spectrum of the cut & symmetry analysis and polishing .

rough diamond cutting machine

"DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets in a single process. The DaVinci system also allows fancy shaping. "DaVinci Diamond Factory" is an automated laser cutting and shaping system for diamonds. Rough diamonds can be transformed into brilliant cut diamonds with up to 57 facets in a single process. The DaVinci system also allows fancy shaping.

my house has a metallic smell

The DaVinci Diamond Factory transforms rough diamonds into brilliant cut diamonds with up to 57 facets in a single operation. Polishing processes are reduced to a final smoothing step to remove the remaining thin black carbon layer. The diamond factory consists of a precision CNC machine with a high power green laser, a compact water pump and an ultra pure water unit. The DaVinci system also includes a cam software that reads the planning files and defines the facet cutting order for optimum yield.

Hallmark, 4G is an all-in-one Diamond Processing System that can perform Table Sawing, Crowning, Bruiting, and Cone Blocking with the one-time fixing of the diamond rough. It is the 4th generation laser processing machine with inbuilt software for laser beam stability & robotic CNC control features.Ultrashape MK7, Bettonville’s most advance diamond cutting laser machine features OEM CAD/CAM software compatible with majority of CAD formats and Bettonville’s proprietary postprocessor installed on a powerful HP graphic workstation. It transforms rough diamonds into brilliant cut diamonds in a single fully automated process. In preparation for the laser process, the rough diamond is scanned and planned by an external planning device. Stone parameters are then transferred to the DaVinci system.The LAZER GRN ng uses the green laser, which works on short wavelength and provides fierce power and precision. The accuracy in cutting results into minimum weight loss and lowest possible breakage and hence more yield per cut diamond.

Highly Accurate and Long Life X-Y-Z CNC Stages for accurate cutting performance. Automatic 360° Fixture For twin side sawing. Dust Protective Enclosure For optimum life of optical components.

diamond sarin machine price

diamond laser inscription machine

Learn how to restore a vintage metal bread box using spray paint and a vinyl design. It is easy way to give the metal a new look.

cnc laser diamond cutting machine factory|diamond drill core cutting machine