cmm cnc machine Incorporating Coordinate Measuring Machines (CMMs) in CNC machining offers unparalleled precision, crucial for critical aerospace, automotive, and medical device components. CMMs outperform manual measurements by ensuring .

$19.99

0 · what is coordinate measuring machine

1 · mitutoyo cmm price list

2 · mitutoyo cmm machine price

3 · made to measure cmm

4 · least count of cmm machine

5 · coordinate measurement machine cmm

6 · cmm inspection machines

7 · cmm catalogue

$49.99

Welcome to our comprehensive guide on Coordinate Measuring Machines (CMM), a cornerstone in modern manufacturing and quality control processes. In this article, we will delve deep into .A CMM, or Coordinate Measuring Machine, is a device used in industrial settings to measure the physical geometrical characteristics of an object.CMM machines ensure that manufacturing .

Mitutoyo manufactures top-quality coordinate measuring machines (CMM) that lead the industry in precision. Find the perfect solution for you. The CMM machine stands out as a beacon of precision and reliability in today’s rapidly advancing CNC machining. As an acronym for Coordinate Measuring Machine, this state-of-the-art equipment plays a pivotal . #cncmachining #coordinatemeasuringmachine In this video, you'll learn what CMM (coordinate measuring machine) is and how it works for CNC Machining. We'll also be discussing the different.

Incorporating Coordinate Measuring Machines (CMMs) in CNC machining offers unparalleled precision, crucial for critical aerospace, automotive, and medical device components. CMMs outperform manual measurements by ensuring . 1. Bridge CMM Machine. The bridge-type coordinate measuring machine is the most popular style. The typical 3D bridge CMM machine allows the probe to move along X, Y and Z, which are orthogonal to each other, each .

The abbreviation CMM stands for Coordinate Measuring Machine, a device that employs coordinate technology to assess the dimensions of CMM machinery or tool components. This includes determining height, width, and depth along the .

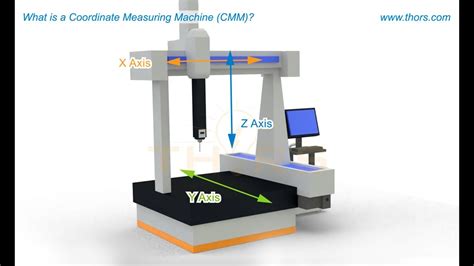

Explore the essentials of Coordinate Measuring Machines (CMMs), their components, applications across industries, benefits, and considerations for optimal manufacturing precision and efficiency. CMM machine stands for Coordinate Measuring Machine. It is a tool that can measure the dimensions of a machine/tool parts using coordinate technology. The dimension open to measurements include the height, width and depth in the X, Y, and Z axis.

what is coordinate measuring machine

cnc glass seaming machine manufacturer

Welcome to our comprehensive guide on Coordinate Measuring Machines (CMM), a cornerstone in modern manufacturing and quality control processes. In this article, we will delve deep into what CMM machines are, how they function, and why they are pivotal in various industries.A CMM, or Coordinate Measuring Machine, is a device used in industrial settings to measure the physical geometrical characteristics of an object.CMM machines ensure that manufacturing parts meet exact specifications and tolerances, helping prevent defects and .

Mitutoyo manufactures top-quality coordinate measuring machines (CMM) that lead the industry in precision. Find the perfect solution for you. The CMM machine stands out as a beacon of precision and reliability in today’s rapidly advancing CNC machining. As an acronym for Coordinate Measuring Machine, this state-of-the-art equipment plays a pivotal role in translating design intricacies into tangible products. #cncmachining #coordinatemeasuringmachine In this video, you'll learn what CMM (coordinate measuring machine) is and how it works for CNC Machining. We'll also be discussing the different.

Incorporating Coordinate Measuring Machines (CMMs) in CNC machining offers unparalleled precision, crucial for critical aerospace, automotive, and medical device components. CMMs outperform manual measurements by ensuring precise adherence to specifications. 1. Bridge CMM Machine. The bridge-type coordinate measuring machine is the most popular style. The typical 3D bridge CMM machine allows the probe to move along X, Y and Z, which are orthogonal to each other, each axis has a sensor for monitoring the probe position, usually with micrometer precision.

cnc grinding machine bit drawing

The abbreviation CMM stands for Coordinate Measuring Machine, a device that employs coordinate technology to assess the dimensions of CMM machinery or tool components. This includes determining height, width, and depth along the X, Y, and Z axes. Explore the essentials of Coordinate Measuring Machines (CMMs), their components, applications across industries, benefits, and considerations for optimal manufacturing precision and efficiency. CMM machine stands for Coordinate Measuring Machine. It is a tool that can measure the dimensions of a machine/tool parts using coordinate technology. The dimension open to measurements include the height, width and depth in the X, Y, and Z axis.Welcome to our comprehensive guide on Coordinate Measuring Machines (CMM), a cornerstone in modern manufacturing and quality control processes. In this article, we will delve deep into what CMM machines are, how they function, and why they are pivotal in various industries.

A CMM, or Coordinate Measuring Machine, is a device used in industrial settings to measure the physical geometrical characteristics of an object.CMM machines ensure that manufacturing parts meet exact specifications and tolerances, helping prevent defects and .Mitutoyo manufactures top-quality coordinate measuring machines (CMM) that lead the industry in precision. Find the perfect solution for you.

The CMM machine stands out as a beacon of precision and reliability in today’s rapidly advancing CNC machining. As an acronym for Coordinate Measuring Machine, this state-of-the-art equipment plays a pivotal role in translating design intricacies into tangible products. #cncmachining #coordinatemeasuringmachine In this video, you'll learn what CMM (coordinate measuring machine) is and how it works for CNC Machining. We'll also be discussing the different.Incorporating Coordinate Measuring Machines (CMMs) in CNC machining offers unparalleled precision, crucial for critical aerospace, automotive, and medical device components. CMMs outperform manual measurements by ensuring precise adherence to specifications.

1. Bridge CMM Machine. The bridge-type coordinate measuring machine is the most popular style. The typical 3D bridge CMM machine allows the probe to move along X, Y and Z, which are orthogonal to each other, each axis has a sensor for monitoring the probe position, usually with micrometer precision.The abbreviation CMM stands for Coordinate Measuring Machine, a device that employs coordinate technology to assess the dimensions of CMM machinery or tool components. This includes determining height, width, and depth along the X, Y, and Z axes.

mitutoyo cmm price list

cnc grinding machine pdf

CNC Machining ABS Parts Manufacturer in China. One of the most reliable plastic CNC machining services manufacturers in China – JTR, with a professional engineering team and skilled machines operator, also 70 advanced CNC machining centers we are capable to complete the ABS CNC machining efficiently.

cmm cnc machine|cmm inspection machines