best tig welding rod for sheet metal $25.30

Perhaps the most coveted lunch container, produced by Universal, features the Man of Steel. Bellomo ranks the box—which shows Superman battling robots and rescuing a damsel in distress—as the most.

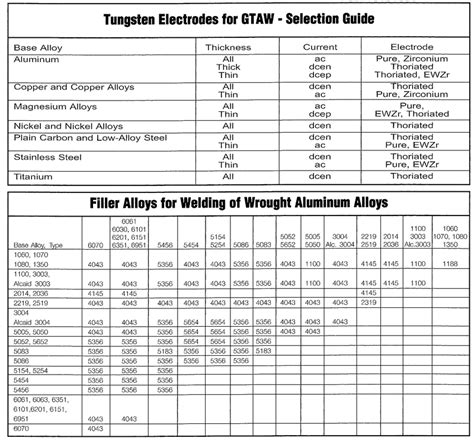

0 · welding filler rod size chart

1 · tig welding wire chart

2 · tig welding rod size chart

3 · tig welding rod selection chart

4 · tig welding mild steel chart

5 · tig rod size chart

6 · stainless steel tig rod chart

7 · stainless steel filler rod chart

Valley Sheet Metal Works is located at 109 Martin St in Water Valley, Mississippi 38965. Valley Sheet Metal Works can be contacted via phone at 662-473-1106 for pricing, hours and directions. Contact Info

Below is chart to select tig welding rod for different stainless steel grades. On X-axis & Y-axis, base metals are given. By matching them as shown in grey color, you can find the suitable tig welding rod for any stainless steel . Learn how to select the right TIG welding filler rod size and composition with helpful guidelines and charts..38.97

.00.30.85.25

welding filler rod size chart

312 is a high strength stainless filler with a generous amount of ferrites to prevent cracking. As an all purpose maintainance filler it is recommended for welding steel to steel, steel to stainless steel, and stainless . In this guide, we’ll explore each aspect that goes into proper TIG welding filler rod selection from material types and sizes to strength charts so you have everything you need to make an informed decision about what will work . GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). We’ll use TIG welding for the rear patch. The first steps are identical to the front — overlapping, adjusting and clamping the patch panel into place, scribing the edge, and then trimming and adjusting the panel to get a .

Whether welding stainless sheet metal or doing some basic mild steel welding, you need proper tungsten electrodes and filler metal to achieve a quality weld. This article provided an overview of which rod to use for what metal. Below is chart to select tig welding rod for different stainless steel grades. On X-axis & Y-axis, base metals are given. By matching them as shown in grey color, you can find the suitable tig welding rod for any stainless steel material grade.

Learn how to select the right TIG welding filler rod size and composition with helpful guidelines and charts. 312 is a high strength stainless filler with a generous amount of ferrites to prevent cracking. As an all purpose maintainance filler it is recommended for welding steel to steel, steel to stainless steel, and stainless steels of unknown composition. In this guide, we’ll explore each aspect that goes into proper TIG welding filler rod selection from material types and sizes to strength charts so you have everything you need to make an informed decision about what will work best for your project!

GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). We’ll use TIG welding for the rear patch. The first steps are identical to the front — overlapping, adjusting and clamping the patch panel into place, scribing the edge, and then trimming and adjusting the panel to get a nice, tight fit. . Either filler is good unless you are anodising it then go for 5356. 4043 will be more ductile and less likely to crack but on the other hand 5356 is a stronger material but tends to crack if you don't cap the weld properly. 5052 is also used a lot in marine applications. if it was going to be exposed to the elements i would use 5356.

TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise heat input and weld placement. For TIG welding, start by thoroughly cleaning the surfaces to be welded with a wire brush or sandpaper before using a high-frequency start to begin the arc. Select an appropriate filler rod for the thickness of the metal being welded .

tig welding wire chart

Whether welding stainless sheet metal or doing some basic mild steel welding, you need proper tungsten electrodes and filler metal to achieve a quality weld. This article provided an overview of which rod to use for what metal.

Below is chart to select tig welding rod for different stainless steel grades. On X-axis & Y-axis, base metals are given. By matching them as shown in grey color, you can find the suitable tig welding rod for any stainless steel material grade.

Learn how to select the right TIG welding filler rod size and composition with helpful guidelines and charts. 312 is a high strength stainless filler with a generous amount of ferrites to prevent cracking. As an all purpose maintainance filler it is recommended for welding steel to steel, steel to stainless steel, and stainless steels of unknown composition. In this guide, we’ll explore each aspect that goes into proper TIG welding filler rod selection from material types and sizes to strength charts so you have everything you need to make an informed decision about what will work best for your project! GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

We’ll use TIG welding for the rear patch. The first steps are identical to the front — overlapping, adjusting and clamping the patch panel into place, scribing the edge, and then trimming and adjusting the panel to get a nice, tight fit. .

Either filler is good unless you are anodising it then go for 5356. 4043 will be more ductile and less likely to crack but on the other hand 5356 is a stronger material but tends to crack if you don't cap the weld properly. 5052 is also used a lot in marine applications. if it was going to be exposed to the elements i would use 5356.TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise heat input and weld placement.

tig welding rod size chart

tig welding rod selection chart

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)

best tig welding rod for sheet metal|tig welding mild steel chart