designing for sheet metal fabrication This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: . Selecting the best gauge for metal roofing involves considering factors such as climate, budget, building structure, and aesthetic preferences. Thicker gauges, such as 24-gauge and 22-gauge, offer enhanced durability and longevity, making them suitable for .

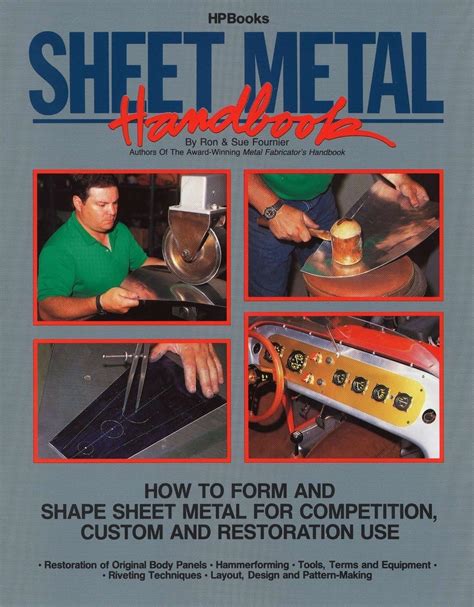

0 · sheet metal handbook free download

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guideline pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal bending guide pdf

There are two types you need to consider to find a suitable TV amplifier for your needs. These are preamplifiers and distribution amplifiers. A preamplifier compensates for signal loss from a long cable run. Meanwhile, a .

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet .

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: .

Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to . Unlock the full potential of sheet metal fabrication with our comprehensive guide! Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

sheet metal handbook free download

sheet metal fabrication handbook pdf

diameter of #8 sheet metal screw

Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to control the machines to cut and form the sheets into the final Unlock the full potential of sheet metal fabrication with our comprehensive guide! Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project. Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.

Deciding to use—or simply consider—sheet metal for an application is the first step in a process. The process begins, of course, with function, which in turn dictates design. Choosing a material and gauge are critical steps that involve balancing factors like strength, weight, and cost.Sheet Metal Design: The Future of Sheet Metal Design. With its long history of engineering and craftsmanship, sheet metal design is poised for a bright future. This discipline, rooted in tradition but propelled by technological advancements, is set to undergo transformational shifts that redefine its aesthetics and functionality. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to control the machines to cut and form the sheets into the final Unlock the full potential of sheet metal fabrication with our comprehensive guide! Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project.

Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.Deciding to use—or simply consider—sheet metal for an application is the first step in a process. The process begins, of course, with function, which in turn dictates design. Choosing a material and gauge are critical steps that involve balancing factors like strength, weight, and cost.

diagonal metal brackets for 4 x 10

sheet metal die design pdf

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

designing for sheet metal fabrication|sheet metal design calculations pdf