sheet metal shop equipment layout Research is essential when buying the heavy machinery required to compete in the sheet metal and HVAC sector. SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop .

Floor junction box or floor access outlet is essential for underfloor wiring and cable management. Traditionally, GI or MS fabricated floor boxes have been used. But there are some serious disadvantages.

0 · sheet metal shop layout

1 · sheet metal fabrication shop

2 · fabrication shop layout template

3 · fabrication shop layout design

Underground pull boxes are used when pulling, splicing, accessing, and storing cable, as well as providing a safe, durable and cost effective housing for system equipment. They can be used in electrical utilities, telecommunications, C&I, water, DOT, .

These magnetic tables have been available for over 50 years and will serve your manual start-up shop quite well until your growth can justify a plasma cutting machine.These tables incorporate two magnets to hold the sheet in place, two rolling shears for both the 5-foot sheet end and for the 10-foot sheet . See more

These standard open-arm sheet storage racks are commonly used and are available new and used. You will need a five-tier rack . See moreThis machine will be your primary longitudinal seam former for the majority of your ductwork and fittings. It is a very important machine. It . See morePittsburgh machinewith “3-1” rolls. This machine is for running Pittsburgh seams on heavier metal. On the opposite side, it will be set up with 3-1 rolls. The 3-1 rolls are necessary to efficiently roll-form taps in edges, flanges for standing seams and female standing . See moreThis machine will serve the lighter gauges for the female Pittsburgh. It should: 1. Form small female Pittsburgh seams on light-gauge metal. 2. . See more

Research is essential when buying the heavy machinery required to compete in the sheet metal and HVAC sector. SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop .Introduction. A well-organized sheet metal fabrication shop layout is crucial for maximizing efficiency, productivity, and safety. By optimizing your shop's layout, you can reduce wasted .

sheet metal shop layout

By Tim Heston. August 25, 2022. Article. Shop Management. Nordroden / iStock / Getty Images Plus. Almost a decade ago during a lean manufacturing seminar hosted by the Fabricators & Manufacturers Association, the late Dick Kallage, . Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.We asked Mike Bailey, Mestek Machinery’s vice president of sales and product development, to go over five commonly overlooked items that can trap sheet metal contractors when putting together their new shops.

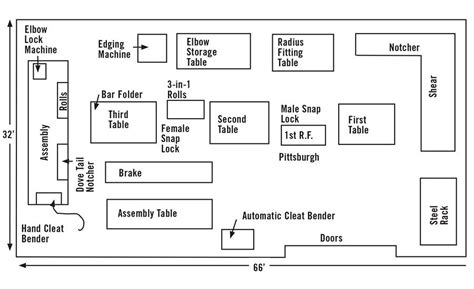

Classic sheet metal shop layout ideas from an industry expert. The following is taken from the revised second edition of Sheet Metal Shop Layouts, published by Snips in September 1981. Figures used have not been adjusted . A plant’s layout affects how everything flows through the system—raw material, work in process (WIP), personnel, visitors, suppliers, customers, machinery, fixtures, tools, and information. The following blog post is part three of a multi-part series in which Mestek Machinery discusses the importance of a good shop layout and the ways in which our customers can .There are a variety of different effective shop layouts, depending on the way your building is constructed. As a sheet metal machinery provider, Acra also offers a service to help with your layout if you’re looking for assistance, or even just a .

i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" .

Basically, a shop layout is a floor plan showing all the machinery, equipment and materials needed, beginning with the receipt of the raw materials (sheet metal and other items) and progressing to the shipment of the . Whether you’re a sheet metal worker planning to eventually open your own shop or a very small company owner ready to expand beyond the world of hammers and snips, knowing what equipment to invest in is essential.. Not . Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best practices to consider: Equipment Maintenance: Equipment maintenance is a crucial aspect of sheet metal fabrication, ensuring optimal performance and longevity of the machinery. Regularly maintaining and . Almost a decade ago during a lean manufacturing seminar hosted by the Fabricators & Manufacturers Association, the late Dick Kallage, longtime industry consultant, pointed to a proposed shop layout.It had a simple elegance to it: just a row of lasers and punches feeding a row of press brakes, followed by a row of welding and assembly cells.

A proper shop layout takes into account the future use of the space a shop has to work with. If a shop needs to make minor adjustments, is it set up so that rearrangements can be made at a minimum cost? 6.) Overall Integration. Merging the first five principles of shop layout is vital to implementing an efficient shop layout into a sheet metal . List all equipment in the shop and draw to scale the equipment or machinery to be considered in the layout, such as mobile tables, benches, A-frames, steel storage racks, vertical racks, brakes, notchers, roll formers, etc. Draw symbols for these items on cardboard or colored paper; cut them out and label them.

Sheet Metal, Duct Fab & HVAC supplies—Founded in 1874 Main Menu. Our Products Menu Toggle. . While we regard it as an essential machine in most any Duct shop, there have been shops will a skilled layout man that have managed without one. .This includes your shop layout, as this can help your workers be more efficient. In this article, we’ll be running through some ways to make positive improvements to the layout of your shop. After analysing the flow of your operation, it might also be a good idea to consider getting new equipment to increase productivity. Effective shop layoutTechnicians will generally connect the process flow in detail with the process director of the plant, and then issue the graphic design scheme. So what research do we need to do about the basis of layout design of sheet metal workshop? 1. Layout design of sheet metal workshop: what should be considered? - Understand the project backgroundPrecision sheet metal workers commonly fabricate and install gutters, sheet metal roofs, and louvers on new buildings. False; Architectural sheet metal worker . The Joint Apprenticeship and Training Committee determines the number of apprentices employed by a particular shop. True. The Joint Apprenticeship and Training Committee is composed .

Richard S Budzik & George Kuprianczyk Practical Guide for Improving Your Metal Fabricating Shop Layout. FREE SHIPPING. This is a Hard back book. 509 Pages. Table of contents: (1) Shop Layout Considerations, (2) Machinery and Equipment Considerations, (3) Important Factors to Consider when Determining New Shop Layout,

The equipment you see on this site is hand-picked from top manufacturers around the world with over 50 percent made in the USA! We aren't limited to offering you one tool brand but choose the best in each category to provide options for the home shop, as well as for professional use, and we back it all up with our No-Junk Guarantee.1,427 Sheet Metal Layout jobs available on Indeed.com. Apply to Sheet Metal Mechanic, Metal Fabricator, Metal Worker and more! . Must have minimum of 2 years of shop sheet metal experience. Plan, layout and install low, . Operate hand and automated metal and sheet metal fabrication equipment.

Knowing how to inspect sheet metal parts can help you better communicate with your metal parts suppliers and foster a stronger, more collaborative relationship. With that in mind, let’s dive deeper into the types of .Tin Knocker’s sheet metal fabrication machines are designed with small- to mid-sized contractors in mind. We strive to provide high-quality machinery at prices that all shops can afford. . Need one machine or an entire shop, Tin Knocker .

practical works in welding and sheet metal shop and demonstration of various aspects: 1. Workshop Practice helps the student to know how the work on shop floor is carried out. 2. To impart knowledge and skill to use tools, machines, equipment, and measuring instruments. Educate students of Safe handling of machines and tools.

This document provides information about a Manufacturing Practice laboratory course for mechanical engineering students. The course objectives include introducing concepts like product dismantling and assembly, pneumatic components, sheet metal tools and operations, welding and soldering, plumbing tools, and 3D printing. It outlines 6 labs that will be covered over 2 cycles, .

REDUCED Sheet metal shop equipment. . 3200.00 Tin knocker 30” cleat bender on stand 20ga 1000.00 Lockformer cheek bender model 24 900.00 5x10 heavy duty layout table 100.00 10-12 sheets 48x96 26ga metal 400.00 15,000.00 take all otherwise as .Sheet Metal Tools and Equipment Sheet Metal Overview Sheet metal workers must complete a variety of tasks using numerous hand tools, power tools, and. stationary equipment. Knowing which tool to choose and how each is used are important skills every. craftworker must learn. Equally important is the knowledge of safety and maintenance . Shop drawings should be created by someone in the company familiar with detailing. Detailing is the process of taking the engineered set of drawings and converting them into shop drawings that the field will use to install the sheet metal. Sheet Metal Detailer. The sheet metal detailer’s job is to coordinate the layout of the ductwork with . Figure 2 1×2400t+3×1000t automatic stamping production line (3) Auxiliary Area. Die Repair; A simple machine repair setup is typically located in the stamping workshop for convenient, daily repairs of the dies.

Sheet metal shop equipment. ,345. Listed 4 hours ago. 4 hours ago. in Tipton, MO. Message. Message. Save. Save. Share. Details. . 3500.00 Tin knocker 30” cleat bender on stand 20ga 1000.00 Lockformer cheek bender model 24 900.00 5x10 heavy duty layout table 100.00 10-12 sheets 48x96 26ga metal 400.00 15,000.00 take all otherwise as . Plan for success when re-designing your metal fabrication or HVAC shop floor layout in 2022. 1-800-665-8089; [email protected]; About. Manufacturers; Careers; . equipment and tooling is easily accessible. . 50 Ways to Remove Excess Work From Your Sheet Metal Shop. fabrication shop layout | Backed by over 100 years of expertise and experience in metal forming and fabrication, The Mestek Machinery Blog is where HVAC duct and fittings manufacturers and fabricators and other industry professionals can learn more about the technologies and processes that drive your operations. . 5 Pieces of Equipment A .Benoit Sheet Metal Equipment, Inc. has an extensive inventory of new and used sheet metal equipment in our warehouse in Kent, Washington. We are located about 20 miles South of downtown Seattle. Area Served We pick up and deliver in the greater Puget Sound area and ship all over the country. *Prices subject to change

The Importance of Good Shop Layout By Richard S. Budzik originally appeared in SNIPS Magazine. The sheet metal contractor should consider the following general principles when determining a new or better shop layout: Work flow. You want to arrange each work area in the sequence in which it performed when making the specific items. Minimum distance.

sheet metal fabrication shop

$29.99

sheet metal shop equipment layout|sheet metal fabrication shop