sheet metal forming force calculation Calculate the required force to deep draw a piece of sheet metal based on the drawing ratio, sheet thickness, and the ultimate tensile strength of the material. In roofing applications, zinc is typically alloyed with small amounts of titanium and copper to enhance its strength and durability. This alloy is then formed into sheets or shingles that can be installed on various types of buildings, from residential .

0 · sheet metal tensile strength calculation

1 · sheet metal shearing force calculation

2 · sheet metal forming tools

3 · sheet metal forming dimensions

4 · sheet metal forming

5 · sheet metal form height ratio

6 · sheet metal form height formula

7 · shearing force of sheet metal

Our No Assembly Box Spring is not your average foundation. Its folding design .

how to repaint a metal tool box

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius .Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary .

The shearing force required depends on various factors, including the material properties of the sheet metal (such as its shear strength), the thickness of the sheet, the cutting method, and the geometry of the cut.Deep Drawing Force Calculator. Sheet thickness (in): Blank diameter (in): Punch diameter (in): Ultimate tensile strength (psi): Factor of safety: Drawing ratio:Calculate the required force to deep draw a piece of sheet metal based on the drawing ratio, sheet thickness, and the ultimate tensile strength of the material. This chapter first introduces sheet metal forming processes, including their industrial importance. The principal strain increments in uniaxial loading are analyzed using .

how to repair a loose electrical box

Calculation Example: The force required for bending sheet metal is given by the formula F = (?UTS * t) * (K * R + t), where ?UTS is the ultimate tensile strength of the sheet . This calculator provides the calculation of strain and deflection of a sheet metal under uniaxial tension. Explanation Calculation Example: Sheet metal forming is a .Air Bending – One of the three types of bending for sheet metal where the outside mold line is not pressed against the die. Air Bend Force Chart – A chart used to calculate the tonnage required for a bend based on thickness, tooling and length.Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Deep Drawing Force Calculator. Sheet thickness (in): Blank .

F = S p dt, where F is the maximum punch force in pounds, S is the nominal tensile strength of the material being drawn (psi), d is the punch or cup diameter and t is the blank thickness. Thus, the force equals pressure times .vol.4 forming tool. vol.5 material for tooling. vol.6 for clearance of the cutting die. vol.7 about turret punch press machine. vol.8 various kinds of special shape. vol.9 parts name of standard tooling. vol.10 each names of forming tool. vol.11 .

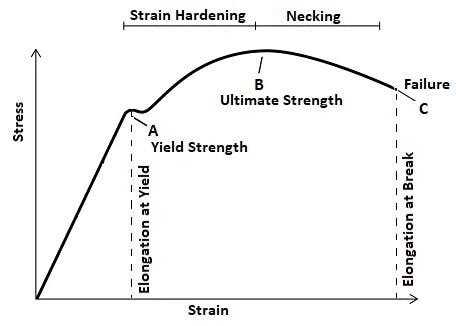

Advanced simulation technology calculates tonnage for even the most complex sheet metal forming process: Using advanced simulation technology, every force of every step of a sheet metal forming process can be calculated using the Finite Element Method (FEM/FEA).Although FEA is certainly based on calculations, the calculations are of a different nature and consider a . Force for Bending Sheet Metal. This calculator provides the calculation of force required for bending sheet metal. . The forming factor is a material property that takes into account the strain hardening behavior of the sheet metal. A higher forming factor indicates that the material is more resistant to bending, and therefore requires a .Bending force, also known as the bending moment or flexural strength, is the force applied to a metal sheet to induce a permanent change in its shape through plastic deformation. The process involves compressing the material on one side (the inside of the bend) while stretching it on the other (the outside of the bend). Several factors .If you’re utilizing 3D CAD software, d raw the part with the flanges in place using the sheet metal function in whatever CAD software you are using. Once you have the flanges in place, edit the bend radius to match the advanced details found at the bottom of the bending calculator.

Calculation Example: Sheet metal forming is a manufacturing process that involves the shaping of metal sheets into various forms. It is widely used in industries such as automotive, aerospace, and construction. . Force: N: w: Width: mm: t: Thickness: mm: Y: Young’s Modulus: GPa: Calculation Expression. Stress Function: The stress on the . The concept of springback is fundamental in sheet metal forming and manufacturing processes. When metal is bent into a specific shape, it often experiences a partial return toward its original form due to the elastic properties of the material. . Relative Force Calculator Heat Rejection Calculator Product Sales Calculator Mg to Percentage .

According to the force balance, the force of each working roll on the steel plate can be obtained: In the above formula: F H – Hydraulic output force of lower roller;; F c – Side roll force;; F a – Upper roller plate rolling deformation force.; F a – Upper roll total force;; α 0 – The angle between the force action line of the side roller and the force line of the upper roller.

Calculate the blank diameter needed for sheet metal forming operations such as deep drawing or stamping. Input the material stretch ratio and finished part diameter to determine the required blank diameter. . Calculating Sheet Metal Shearing Force. Calculate the shearing force required to cut sheet metal based on material strength, thickness . The calculation for drawing is similar to that used for blanking except the ultimate tensile strength of the coil material is used because the sides of the shell or cup are in tension during the drawing operation. . The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the . Calculation Example: Sheet metal forming is a manufacturing process that involves the shaping of metal sheets into various forms. The strain and deflection of the sheet metal under uniaxial tension are important factors to consider in the design and analysis of sheet metal forming processes. . Force: N: l: Length: mm: w: Width: mm: t . Sheet metal Forming Process - Download as a PDF or view online for free. . • Example of Force Calculation Calculate the force required to stretch form a wing span having a cross- sectional area of .50X120” made from 2219 aluminum alloy having a yield strength of 36,000 psi and a UTS of 52,000 psi: .

Deep Drawing Calculations. Deep Drawing Calculations and main principles of deep drawing with a hydraulic deep drawing press. Free consultation. Price from the manufacturer. Deep Drawing Calculations. Deep drawing is a metal forming process used to form sheet metal into a desired shape. The process involves drawing a flat sheet of metal into a die .Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, . 1. Material selection: The first step is to choose the right sheet metal material for the job. The type of metal, thickness, strength, and ductility are all factors to consider. 2. Blank preparation: The sheet metal is cut to the size .

to control the rate of metal flow into the die cavity. The force exerted by the binder on the sheet metal supplies a restraining force which controls the metal flow. For flat binder areas (right hand side of Fig. 1) the restraining force is largely friction. The force may be varied by controlling the clamping force be These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD software provides related tools and functions for sheet metal design. For example, Creo offers a variety of methods for .

An introduction Hydroforming is a cost-effective metal fabricating process that can form complex geometries in tubular based parts and extended deep draws in sheet metal-based parts. Hydroformed parts allow for parts consolidation, the reduced number of sub components reduces assembly costs and increases strength and stiffness of the final assembly. Tolerances will . Calculation Example: Sheet metal forming is a manufacturing process that involves the shaping of metal sheets into various forms. The strain and deflection of the sheet metal under uniaxial tension are important factors to consider in the . Sheet Metal Bending Force Formula. In recent years, the press brake machine has gained widespread use across various industries and has expanded its processing capabilities.. Despite its popularity, there has been a lack of systematic discussion on .

For instance, if the sheet metal to be bent is mild steel, with a thickness of 4mm and a bending length of 3.2m, the theoretical width of the bottom die opening should be 8 times the thickness, which is 32mm. Input these figures into the calculator above (remember the units are in mm), and we get a value of 106.12 Ton. This means you’ll need a minimum bending .%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 .

sheet metal tensile strength calculation

Bending Force - (Measured in Newton) - Bending Force is the force required to bend a particular material about an axis. Bending Die Constant - Bending Die Constant is a numerical value used in metal working to quantify the relationship between applied force and material deformation during bending operations. Bent Part Length - (Measured in Meter) - Bent Part Length is the portion . For instance, Let's assume a sheet part with thickness 3mm, Kv =2.5, more than 8x of thk., L=60, W=75, S=41 Force = (2.5 x 41 x 75 x 3 x 3) / 60 ⇒ 1153 Kgf To check the accuracy of the formula, the co-relation has been made with the FEA force calculation :Keywords: Deep Drawing, Part Development, Punch velocity and Force, Ansys simulation, force on punch. I. INTRODUCTION Deep drawing is the sheet metal forming process in which sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a mostly use this process in the automobile industry for .

sheet metal shearing force calculation

sheet metal forming tools

The Upholstered Metal Box Spring has the best of both worlds --a look that polishes off your bed and the strength and durability of a metal bed foundation.

sheet metal forming force calculation|sheet metal forming