sheet metal forming bending Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must . HELICHECK PLUS is the universally used measuring machine for both micro-tools and tools in the standard range. Measurements for transmitted light and incident light are performed by the HELICHECK PLUS operator-independent, CNC-controlled and μ-precise.

0 · types of sheet metal bending

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending basics

5 · bending sheet metal by hand

6 · bending sheet metal at home

7 · bending galvanized sheet metal

Limited Edition Deluxe Metal Box incl. The Limited Edition CD, 7" E.P. Vinyl Single with 1 Exclusive Track only available in this box, W.A.S.P. Logo Pendant/Necklace, Poster Flag and Photo-Card with Printed Autograph.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must .Quiz yourself with questions and answers for sheet metal quiz, so you can be ready for test day. . sheet metal bending. machining. sheet metal forming. 1 of 31. Term. . A shearing process where a tool is forced through the sheet metal workpiece forming a hole. punching. shearing. bending. notching. 9 of 31. Term. Punching a number of holes .Sheet Metal Folding Tool: Hurricane 24" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together Two Folding Depths: Creates 3/8" and 1" .

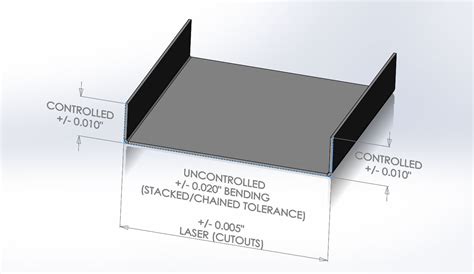

Metal Sheet Forming yang lain Guerin, menggunakan bantalan karet untuk membentuk logam. Metal Sheet Forming yang lain Hidro Forming, menggunakan diafragma karet diisi Fluida bertekanan. Stamping. . Metal compressed Bend Gambar 1.12 (a) Pembengkokkan logam lembaran, (b) pemampatanกระบวนการขึ้นรูปโลหะแผ่น (Sheet Metal Forming Process) เช่น กระบวนการตัด เฉือน (Blanking Process) กระบวนการพับขึ้นรูป (Bending Process) และกระบวนการลากขึ้นรูปลึก (Deep .This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Search Now. Popular search terms. . Forming or bending +/- 0.508 mm (0.020") Bend to hole or feature +/-0.254 mm (0.010")

Metal sheet bending and forming is performed on a press brake machine. To form the workpiece, it is placed on the machine and the brake shoe is lifted by the lifting lever. The workpiece is then positioned correctly, and the brake shoe is lowered onto the workpiece to apply the necessary force for bending and forming.Sheet Metal Folding Tool: Hurricane 18" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together Two Folding Depths: Creates 3/8" and 1" depth folding in ductwork

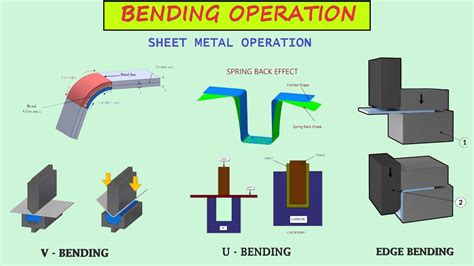

Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. A bending operation causes deformation along one axis, but a sequence of several different operations can .In this process, a bending punch is stamped into the sheet metal placed above the V-die, causing the sheet metal to deform elastically and plastically inside the V-groove, forming a V-shaped bend.The angle of the V-bend depends on the pressure point of the punch and the opening angle of the die, and usually varies between 30° and 120°.The . Keywords: Bending; Metal forming; Incremental forming; Flexible sheet metal forming 1. Introduction Flexible sheet metal forming is important for many industrial sectors such as shipbuilding, chemical engineering and shell structure construction. For example, in shipbuilding industry forming hull surface is one of the key processes.

types of sheet metal bending

Sheet metal forming is commonplace in a variety of industries and everyday items. Read on to find out everything you need to know about sheet metal forming, how it works, and where it’s used. . is bending. Bending sheet metal requires the use of specialized but fairly simple bending tools, like press brakes. The sheet metal bending process . It suggests that the kinematic hardening properties of the sheet metal give the positive effect on forming limit under the stretch-bending condition. It is noted that no significant difference between the forming limit strains under isotropic and kinematic hardening with sharp bending radius ( R / t =1) was found in Fig. 10 . The bending is a sheet-metal forming operation that involves deformation by applying force thereby causing the sheet-material to bend at an angle and form the anticipated shape. Press-bending is a key step in metal sheet manufacture (Corrieri, 2018). Bending, in sheet-metal work, involves the straining of the metal around a straight (neutral) axis.Galaxy offers sheet metal fabrication services since 1989, with a comprehensive range of in-house sheet metal work services including: Prototyping, Laser Cutting, Metal Bending, CNC Punching & Forming, CNC Machining, Welding, a full Powder Coating plant, Assembly, all .

Sheet metal production is as much science as it is a craft and should be treated as such. Summary. In this article, we talked about the metal forming process, the differences between forming and bending, sheet metal forming, and the applications of metal forming techniques. The sheet metal forming process is a unique type of metal forming process which enables the deformation of metals that are less than 6mm in thickness. In our analysis, we considered three different materials i.e.Aluminium, Stainless steel and Carbon steel-1020- annealed, that undergoes Bending stress using V die. The analysis is carried out using Finite .

Sheet metal bending, also referred to as sheet metal forming, is the process of applying force to a piece of sheet metal in order to change its shape. The bending process takes place using an electric, pneumatic or hydraulic press. The two most common shapes are U and V, although the metal can also be formed into corrugations, curls, flanges or other shapes.

Sheet Metal Forming Technology-manual Bending of Sheet Metal. It is difficult to bend a single-piece small batch of sealed or semi-closed bending parts with a machine tool. In this case, manual bending is often used. When bending, first draw a bending line on the unfolded material, and then use a gauge iron to put it on the vise. When clamping . Sheet Metal Bending and Forming Guidelines. We suggest the following design rules to bend the metal parts within our tolerance range of precisely ± 0.25 mm in length and ±1 °. K-factor. It is the ratio of the distance of the neutral axis to the sheet thickness. Maintain K-factor in a range of 0.25 to 0.5.Metal Forming Experts . Bending and rolling of metal can be straight forward or a complex craft. Northern's creativity and experience allow us to tackle the most difficult geometries successfully. . Northern Manufacturing is a sheet metal fabrication company specializing in stainless steel fabrication. Contact Us. Phone: 419.898.2821 Fax: 419 .

When the electro-hydraulic servo press brake machine bends sheet metal parts, three basic parameters are required: the thickness of the sheet, the bending angle, and the position of the bending line. The first and second split . A 90-degree punch would be coupled with a 90-degree V die. The change from folding to forming was a major leap forward for sheet metal. It was faster partly because the newly developed press brake was powered—no more manual folding of every bend by hand. Plus, press brakes could bottom bend, which boosted accuracy.

Laser Cutting Company offers custom metal forming services for laser cut parts using the Bystronic Xpert 150 Press Brake. The Bystronic Xpert Press Brake provides precision bending results coupled with superior repeatability, allowing us to provide you with parts that meet your exact specifications quickly and cost-effectively. Sheet metal forming processes are typically performed at room temperature on machined tools called Presses using Dies. The parts are referred to as “Stampings”. Sheet metalworking processes. Sheet metalworking processes are classified into three categories: bending, sheet metal drawing, and shearing. Shearing – Cutting. Shearing; Blanking .

sheet metal bending standards

Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake.. In this article, we provide a comprehensive guide on sheet metal bump bending with details on the suitable metals you . 4. INTRODUCTION: SHEET METAL FORMING is the process of converting a flat sheet of metal into a part of desired shape without fracture or excessive localized thinning. The process may be simple, such as a bending operation, or a sequence of very complex operations such as those performed in high-volume stamping plants.

sheet metal parameters solidworks

sheet metal north shore

Some fixtures, such as ceiling fans, require specific junction boxes, and a box must be rated to support the weight of any fixture you’re installing. Find Weatherproof junction boxes at Lowe's today. Shop junction boxes and a variety of electrical products online at Lowes.com.

sheet metal forming bending|bending sheet metal by hand