cnc lathe part ejector When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big . The most common types of electrical boxes include junction boxes, outlet boxes, switch boxes, and ceiling boxes. Junction boxes are used to connect wires and cables, while outlet boxes are used to house electrical outlets.

0 · sub spindle ejector instructions

1 · lathe sub spindle ejector

2 · lathe ejector parts diagram

3 · b205 ejector parts

There are various types of corrugated metal roofing available in the market, including galvanized, aluminum, stainless steel, painted, and copper. Each type of corrugated metal roofing has its unique features, advantages, installation .

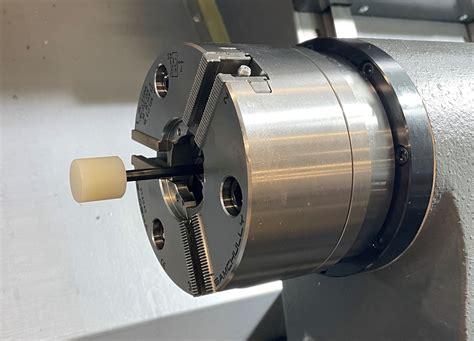

Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible. When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big .

SR-32J/JN CNC Swiss-type Automatic Lathe. New generation design offers power with maximum rigidity and high output drives that are engaged for large diameter components. Excellent . Coupled with a programmable parts catcher, a subspindle ejector makes sure the finished part is out of the machine. The ejector is an especially .SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter .

CNC Machine Services Tech Bulletin #DO-0101 Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, . So I am machining copper in our new LB2000 EX. Great machine thus far. Machine is equipped with Hardinge Quick Change collets on both the main and sub spindles .A simple part ejector can be employed. This ejector is normally pneumatic or hydraulic and is sent forward to push the part out of the subspindle after the machining work is completed. Some .

Line the part ejector [1] up with the hole in the sub spindle, and press it in. The part ejector [1] will stop against an internal lip in the draw bar [2], press it in until movement stops. Note: The sub spindle jaws may need to be unclamped or removed for .Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible. When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big bill to repair the damage. If you are plagued by this problem, you will be interested in the Subspindle Part Ejection Device (SPED) made by Zenna Industries.

SR-32J/JN CNC Swiss-type Automatic Lathe. New generation design offers power with maximum rigidity and high output drives that are engaged for large diameter components. Excellent balance of operability, high productivity and efficiency; High productivity is .

sub spindle ejector instructions

Coupled with a programmable parts catcher, a subspindle ejector makes sure the finished part is out of the machine. The ejector is an especially important feature for lights-out machining. Sufficient axis travels are important for tool and workpiece clearance.SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter 20mm; Flexible tooling layouts allow for endless variations of complex machining CNC Machine Services Tech Bulletin #DO-0101 Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, with one tip, approximately 0.750 in diameter. This tip will not eject a part smaller than the diameter, and in fact, may hit the back of the collet So I am machining copper in our new LB2000 EX. Great machine thus far. Machine is equipped with Hardinge Quick Change collets on both the main and sub spindles and a spring ejector on the sub. My problem comes on part ejection.

A simple part ejector can be employed. This ejector is normally pneumatic or hydraulic and is sent forward to push the part out of the subspindle after the machining work is completed. Some subspindle manufacturers use a spring loaded system .This parts ejector from 1st Machine Tool Accessories can be used to capture collet chucks between the sleeve and the drawnut.

Line the part ejector [1] up with the hole in the sub spindle, and press it in. The part ejector [1] will stop against an internal lip in the draw bar [2], press it in until movement stops. Note: The sub spindle jaws may need to be unclamped or removed for .

Our highly functional part ejector design allows for easy part loading and ejection to facilitate automated machining. This design is adjustable for various part lengths, making it adaptable and flexible. When parts fail to eject properly from the subspindle of a four-axis lathe or Swiss screw machine, the result can be hours of downtime and a big bill to repair the damage. If you are plagued by this problem, you will be interested in the Subspindle Part Ejection Device (SPED) made by Zenna Industries.SR-32J/JN CNC Swiss-type Automatic Lathe. New generation design offers power with maximum rigidity and high output drives that are engaged for large diameter components. Excellent balance of operability, high productivity and efficiency; High productivity is . Coupled with a programmable parts catcher, a subspindle ejector makes sure the finished part is out of the machine. The ejector is an especially important feature for lights-out machining. Sufficient axis travels are important for tool and workpiece clearance.

SB-20R Type G CNC Swiss-type Automatic Lathe. The SB-20R Type G offers a wide range of machining operations that is made possible with the unique Guide Bush/Non-Guide Bush switching function. Maximum machining diameter 20mm; Flexible tooling layouts allow for endless variations of complex machining CNC Machine Services Tech Bulletin #DO-0101 Doosan Puma Work Ejector Tip Replacement The Puma series machines with sub-spindle may have an optional work ejector, with one tip, approximately 0.750 in diameter. This tip will not eject a part smaller than the diameter, and in fact, may hit the back of the collet So I am machining copper in our new LB2000 EX. Great machine thus far. Machine is equipped with Hardinge Quick Change collets on both the main and sub spindles and a spring ejector on the sub. My problem comes on part ejection.A simple part ejector can be employed. This ejector is normally pneumatic or hydraulic and is sent forward to push the part out of the subspindle after the machining work is completed. Some subspindle manufacturers use a spring loaded system .

lathe sub spindle ejector

This article explores the types of stainless steel sheets, including their unique properties and applications. Readers will gain insight into how these materials enhance product longevity and efficiency across different sectors.

cnc lathe part ejector|sub spindle ejector instructions