complex sheet metal forming The growing interest in sheet metal stamping processes, particularly in automotive industry, led to three main issues in this field: request of very complex shapes; growing interest in springback control; solution of multi-objective problems. Prepare to be awestruck by this breathtaking all-white kitchen, adorned with pristine flat-panel cabinets, sleek stainless steel appliances, and gleaming white countertops, effortlessly complemented by a striking white slab backsplash.

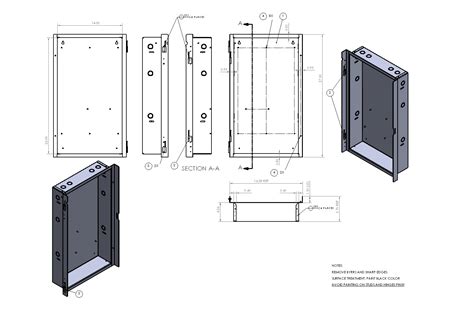

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

$74.98

The growing interest in sheet metal stamping processes, particularly in automotive industry, led to three main issues in this field: request of very complex shapes; growing interest in springback control; solution of multi-objective problems.The main processes of sheet metal forming like deep drawing, rolling and bending .This article focuses on the simulation of complex-shaped parts made from a . Sheet-metal forming is one of the most important manufacturing processes in the automotive industry. This study proposes a multiobjective optimisation scheme that controls both sheet-metal formability and springback.

The growing interest in sheet metal stamping processes, particularly in automotive industry, led to three main issues in this field: request of very complex shapes; growing interest in springback control; solution of multi-objective problems.

Sheet-metal forming is one of the most important manufacturing processes in the automotive industry. This study proposes a multiobjective optimisation scheme that controls both sheet-metal formability and springback. The development of additive manufacturing-sheet forming (AM-SF) hybrid manufacturing process aims to address the problems faced by single manufacturing processes, such as the high cost of additive manufacturing and . The main processes of sheet metal forming like deep drawing, rolling and bending allow the production of complex structural and functional components, such as parts used for car body construction, housings and mechanical and mechatronic systems.

A method is designated for forming a part from a sheet metal blank into a final design shape that has critical forming areas, which can be exemplified by the shape shown in Fig. 1. The method comprises drawing the blank to form an intermediate shaped part that includes a bulge adjacent to the critical region.

This article focuses on the simulation of complex-shaped parts made from a titanium alloy (Ti6Al4V) using incremental sheet metal forming (ISMF). The simulations were conducted through finite element (FE) analysis using the ABAQUS® software package. Linear brick. Sectional multi-point forming (SMPF) technology provides a new solution for forming large-size sheet metal. With this technique, large-size parts of sheet metal can be manufactured on a. Incremental sheet metal forming (ISMF) is a viable method for fabricating complicated three-dimensional structures from sheet metal. It is characterized by localized deformation and is effective . Two investigated examples show the application of the method for complex planning situations. The first one uses variable functions of force and motion during deep drawing to extend the process limits. The second one describes the complex clamping of an assembly of different sheet metal parts.

This study aims at exploring the potentialities of cold orbital forming in forming complex sheet metal. Aiming at a complex mobile phone shell component of aluminum alloy, two technical schemes for cold orbital forming are first presented. The growing interest in sheet metal stamping processes, particularly in automotive industry, led to three main issues in this field: request of very complex shapes; growing interest in springback control; solution of multi-objective problems. Sheet-metal forming is one of the most important manufacturing processes in the automotive industry. This study proposes a multiobjective optimisation scheme that controls both sheet-metal formability and springback. The development of additive manufacturing-sheet forming (AM-SF) hybrid manufacturing process aims to address the problems faced by single manufacturing processes, such as the high cost of additive manufacturing and .

The main processes of sheet metal forming like deep drawing, rolling and bending allow the production of complex structural and functional components, such as parts used for car body construction, housings and mechanical and mechatronic systems.

sheet metal layout drawings

sheet metal forming types

A method is designated for forming a part from a sheet metal blank into a final design shape that has critical forming areas, which can be exemplified by the shape shown in Fig. 1. The method comprises drawing the blank to form an intermediate shaped part that includes a bulge adjacent to the critical region.

This article focuses on the simulation of complex-shaped parts made from a titanium alloy (Ti6Al4V) using incremental sheet metal forming (ISMF). The simulations were conducted through finite element (FE) analysis using the ABAQUS® software package. Linear brick.

Sectional multi-point forming (SMPF) technology provides a new solution for forming large-size sheet metal. With this technique, large-size parts of sheet metal can be manufactured on a.

Incremental sheet metal forming (ISMF) is a viable method for fabricating complicated three-dimensional structures from sheet metal. It is characterized by localized deformation and is effective .

Two investigated examples show the application of the method for complex planning situations. The first one uses variable functions of force and motion during deep drawing to extend the process limits. The second one describes the complex clamping of an assembly of different sheet metal parts.

sheet metal forming process pdf

sheet metal forming press dies

Whole house water filters are a great choice for those who want to be sure that their water supply remains free of certain contaminants, bacteria, sediment, viruses, heavy metals, or even chemicals.

complex sheet metal forming|bulk deformation vs sheet metal forming