6061 aluminum cnc machining One of the most popular aluminum alloys is 6061 aluminum, known for its excellent strength-to-weight ratio and corrosion resistance. Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can . Safety should always be a top priority when dealing with electrical systems: Turn Off Power: Before working on electrical junction boxes, turn off the power supply to prevent electrical shocks. Regular Inspection: Periodically inspect junction boxes for signs of wear, damage, or loose connections.

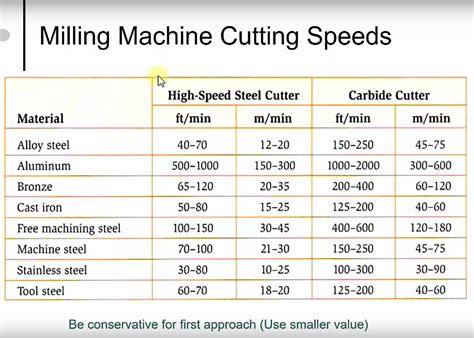

0 · surface speed for 6061 aluminum

1 · sfm range for 6061 aluminum

2 · recommended cutting speed for aluminum

3 · cutting speed for 6061 aluminum

4 · casting 6061 aluminum

5 · aluminum machinability chart

6 · aluminum alloy machinability chart

7 · 6061 aluminum machinability chart

Follow these steps to enter 1099-DIV cash or noncash liquidation distributions in the program: Go to Input Return ⮕ Income ⮕ Dispositions (Sch D, etc.). Select Schedule D/4797/etc. In the Quick Entry grid, select Details to expand. Under Dispositions (Sch D, etc.), enter the Description of Property.

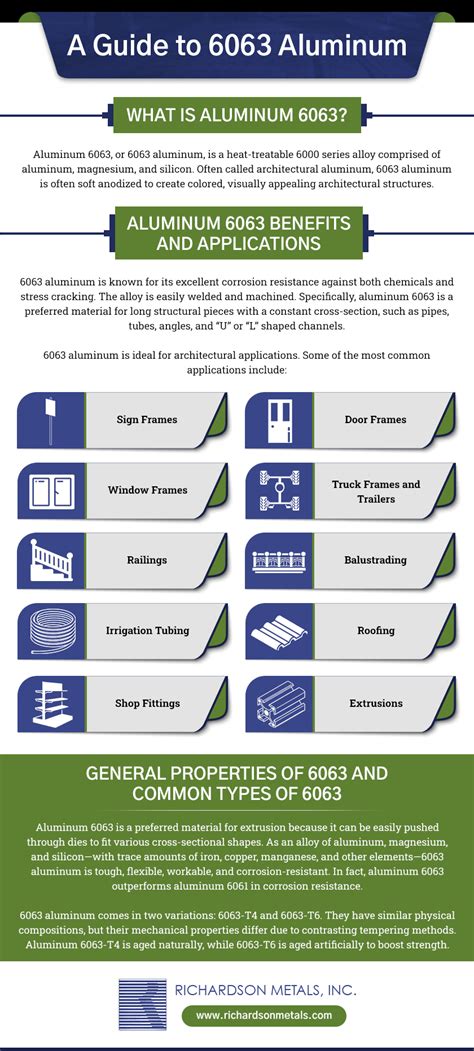

Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition One of the most popular aluminum alloys is 6061 aluminum, known for its excellent strength-to-weight ratio and corrosion resistance. Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can . The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability . 6061-T6 aluminum strength and light weight property make it different from other aluminum alloys. High strength to weight ratio of 6061-T6 .

In this CNC materials video, we show and discuss several parts that were CNC machined using aluminum 6061. We'll also explain the properties of the CNC machi.

Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition One of the most popular aluminum alloys is 6061 aluminum, known for its excellent strength-to-weight ratio and corrosion resistance. Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can achieve exceptional results.

The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability makes it a versatile alloy. 6061-T6 aluminum strength and light weight property make it different from other aluminum alloys. High strength to weight ratio of 6061-T6 Aluminum makes it ideal for aircraft applications. This article would help you to choose 6061-T6 Aluminum for desired application by understanding its properties and features.In this CNC materials video, we show and discuss several parts that were CNC machined using aluminum 6061. We'll also explain the properties of the CNC machi. 6061 is a common aluminum alloy produced by heat treatment and stretching process. With its high strength and corrosion resistance, CNC machining 6061 aluminum products extensively used in industrial structural and more fields.

surface speed for 6061 aluminum

6061 aluminum can be rolled into thin sheets or thick plates, depending on the application. TIG and MIG welding are the most common methods used, with post-weld heat treatment often recommended. The alloy’s excellent machinability makes it suitable for precise CNC machining to create complex parts.6061-T6 aluminum is precipitation-hardened 6061 aluminum. 6061 aluminum is one of the most versatile, common aluminum alloys that may be heat treated. The main alloying elements for 6061 aluminum are silicon and magnesium. 6061 aluminum is a widely used alloy in the 6000 series, offering an excellent balance of strength, corrosion resistance, and machinability. This makes it a popular choice for many CNC machining applications, including aerospace components, automotive parts, and electronic enclosures.

6061-T6 aluminum is a popular choice for CNC machining due to its excellent properties. This grade of aluminum offers good corrosion resistance, making it ideal for use in harsh environments. In addition, its weldability makes it suitable for joining multiple parts together.Aluminium 6061(AlMgSiCu):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition One of the most popular aluminum alloys is 6061 aluminum, known for its excellent strength-to-weight ratio and corrosion resistance. Machining 6061 aluminum can be challenging, but with the right tools and techniques, you can achieve exceptional results. The 6061 aluminum alloy is the most widely used aluminum grade across industries, whether in its angle, bar, sheet, or plate form. The 6061 aluminum’s medium to high strength, good weldability, and machinability makes it a versatile alloy.

6061-T6 aluminum strength and light weight property make it different from other aluminum alloys. High strength to weight ratio of 6061-T6 Aluminum makes it ideal for aircraft applications. This article would help you to choose 6061-T6 Aluminum for desired application by understanding its properties and features.

In this CNC materials video, we show and discuss several parts that were CNC machined using aluminum 6061. We'll also explain the properties of the CNC machi.

6061 is a common aluminum alloy produced by heat treatment and stretching process. With its high strength and corrosion resistance, CNC machining 6061 aluminum products extensively used in industrial structural and more fields.6061 aluminum can be rolled into thin sheets or thick plates, depending on the application. TIG and MIG welding are the most common methods used, with post-weld heat treatment often recommended. The alloy’s excellent machinability makes it suitable for precise CNC machining to create complex parts.

othermill desktop cnc machine

6061-T6 aluminum is precipitation-hardened 6061 aluminum. 6061 aluminum is one of the most versatile, common aluminum alloys that may be heat treated. The main alloying elements for 6061 aluminum are silicon and magnesium. 6061 aluminum is a widely used alloy in the 6000 series, offering an excellent balance of strength, corrosion resistance, and machinability. This makes it a popular choice for many CNC machining applications, including aerospace components, automotive parts, and electronic enclosures.

outdoor electrical box enclosures

sfm range for 6061 aluminum

recommended cutting speed for aluminum

Stopping in a yellow box junction can land you a fine but it's not always your fault meaning the yellow box junction can be more like a yellow box trap. In this video I explain and.

6061 aluminum cnc machining|aluminum machinability chart