aluminum for sheet metal bending Another factor to consider is that during the process of bending, the metal hardens and strengthens by reason of the working effect. Apart from . See more Established in 2015, we are a metal fabrication business with a mechanical engineer and professional welders on staff. We are located just 30 minutes from Charlotte in Lincolnton, NC. For more info, distributor pricing, or to suggest products to us shoot an email to:

[email protected]

0 · thickest aluminum sheet metal bending

1 · is aluminum easy to bend

2 · best way to bend aluminum

3 · best aluminum grade for bending

4 · bending aluminum sheet by hand

5 · bending aluminum pipe by hand

6 · bending 3003 aluminum sheet metal

7 · bending 1 8 aluminum plate

Here's how I have the transformer positioned now, and how I plan to connect it with conduit: The red lines for the 110VAC conduit go behind the .

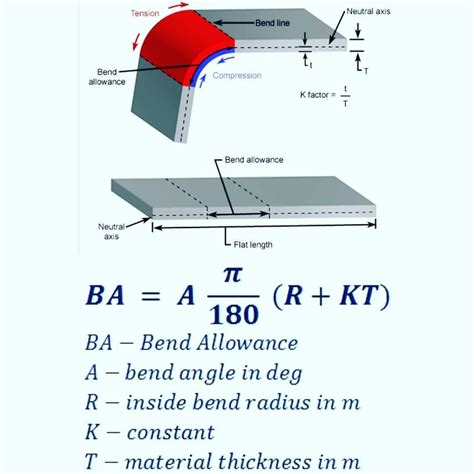

In high purity forms, aluminum is soft and ductile. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Depending on designation, alloys go through different heat treatment . See moreTo understand this better, we need to talk about alloys, which is the first factor to consider upon selection. In aluminum, we have various designations that all have different chemical . See moreAnother factor to consider is that during the process of bending, the metal hardens and strengthens by reason of the working effect. Apart from . See moreIf you’d like to know more about bending specific alloys or which alloy is best for your application, please contact our sales department by calling 800-826-3370. See more

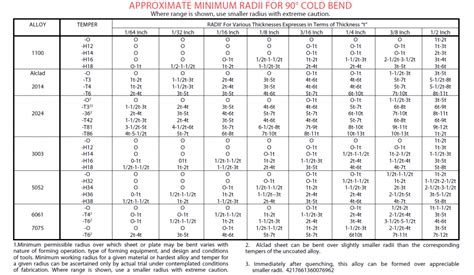

A third factor to be considered is that formability of a specific alloy can be found in the percentage of elongation and the difference between yield strength and ultimate tensile strength. This rule states that the higher the elongation value (the wider the range . See more Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. This is generalizing, of course, as there are ways to form 6061. The aluminum series’ ability to bend .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending ."Which aluminum alloy bends the best?" is a a common question customers want the answer to. In this post, we'll explain it to you. Background In high purity forms, aluminum is soft and ductile. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that

Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. This is generalizing, of course, as there are ways to form 6061. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to T4 and T6.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Aluminum 6061-T6 is notoriously difficult to bend, but skilled press brake operators can tackle the challenges with various strategies, including torch annealing.

6061 Aluminum: Miserable to bend, cracking is very common and cold bending will always weaken the metal. Proper bending can be done with annealing the aluminum first, although it’s not an ideal candidate for formed parts. 5052 Aluminum: Highly formable, and one of the best kinds of aluminum to bend.Bending metal to a small bend radius has the potential to cause tearing or cracking. The Fabricator offers certain key tables and general rules which are helpful for understanding the limits to bendability for specific aluminum alloys. One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you want is through bending. Some aluminium alloys and tempers are better suited for bending than others. This is what you need to know to choose the one that's right for you.

There are a couple standard ways of bending aluminum, depending on the form you’re working with. When bending large sheets, your best bet is to use a metal bending brake, or to improvise one using a sturdy tabletop and a length of scrap wood.The top 3 aluminum alloys for bending are the 3003 which has medium strength and the best cold workability, the 5052 which is the highest strength alloy of the more common non-heat treatable grades, and the 6061 which is one of the more versatile heat-treatable alloys. During aluminum bending, you will transform the material into various shapes using mechanical force. This guide looks at fundamental aspects to consider when bending aluminum such as suitable alloys, factors affecting bending process, bending techniques, to application. So, before starting your next project, read this guide."Which aluminum alloy bends the best?" is a a common question customers want the answer to. In this post, we'll explain it to you. Background In high purity forms, aluminum is soft and ductile. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that

thickest aluminum sheet metal bending

Ideally, part designers should know that when it comes to aluminum grades, 3003 and 5052 will bend, 6061 will not. This is generalizing, of course, as there are ways to form 6061. The aluminum series’ ability to bend tends to decrease as you move down the list of tempers, from annealed to T4 and T6.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Aluminum 6061-T6 is notoriously difficult to bend, but skilled press brake operators can tackle the challenges with various strategies, including torch annealing.6061 Aluminum: Miserable to bend, cracking is very common and cold bending will always weaken the metal. Proper bending can be done with annealing the aluminum first, although it’s not an ideal candidate for formed parts. 5052 Aluminum: Highly formable, and one of the best kinds of aluminum to bend.

Bending metal to a small bend radius has the potential to cause tearing or cracking. The Fabricator offers certain key tables and general rules which are helpful for understanding the limits to bendability for specific aluminum alloys.

One of the most useful characteristics of aluminium is its formability, and one way to form the metal into the shape you want is through bending. Some aluminium alloys and tempers are better suited for bending than others. This is what you need to know to choose the one that's right for you.

There are a couple standard ways of bending aluminum, depending on the form you’re working with. When bending large sheets, your best bet is to use a metal bending brake, or to improvise one using a sturdy tabletop and a length of scrap wood.The top 3 aluminum alloys for bending are the 3003 which has medium strength and the best cold workability, the 5052 which is the highest strength alloy of the more common non-heat treatable grades, and the 6061 which is one of the more versatile heat-treatable alloys.

what size metal box for a 50 amp plug

is aluminum easy to bend

Ametco Manufacturing Corporation manufactures custom Swing gates, V-wheel roller gates and Cantilever gates to complete your enclosure. All three style gates are made for trash enclosures in either galvanized steel or aluminum that after fabrication are .

aluminum for sheet metal bending|bending 1 8 aluminum plate