3d scanning parts for cnc maching part inspection Does it make sense to use a 3D Scanner to inspect CNC machined parts? Typically these parts are hand measured or inspected on a CMM. Is using a 3D Scanner,. If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

0 · scantech for 3d inspection

1 · 3d scanning software

2 · 3d inspection software

3 · 3d inspection scanner

4 · 3d inspection in metrology

Wiremold® Ratchet-Pro™ Series Floor Boxes provide single- and dual-service capability in a variety of easy to-install round floor boxes. These designs allow the flexibility for providing power, A/V or communication services to open-space areas in an aesthetic solution.

scantech for 3d inspection

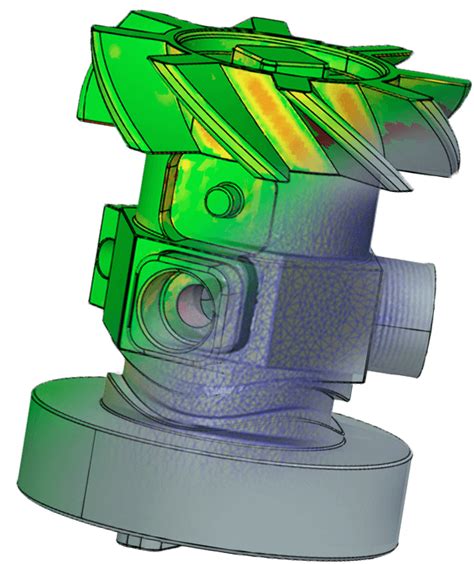

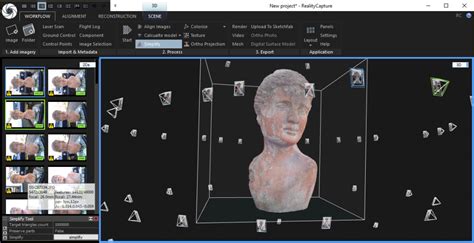

In this article, we’ll discuss the different methods of metrology used for part inspection and how 3D scanning parts for CNC machining can be beneficial for quality assurance, quality control, and tooling inspection. Does it make sense to use a 3D Scanner to inspect CNC machined parts? Typically these parts are hand measured or inspected on a CMM. Is using a 3D Scanner,.The portable 3D scanners offer real-time verification of part assembly, ensuring correct installations and reducing production errors. This guarantees that the final product functions as designed, enhancing reliability.With 30 years of successful 3D laser scanning projects around the globe, Laser Design can help with your reverse engineering and inspection needs. We can scan, model, and inspect parts of all sizes and complexity. Laser Design’s .

3D scanning for inspection has elevated the quality control process by offering more dependable measurements, plug-and-play functionality, and unmatched speed. How do you 3D scan for CNC machined parts? What is the process of creating files ready for machine programming? The 3D scanning process is performed by 3D laser scanners that range in accuracy.

metal site tool box

3D scanners can be used to create semi-automated inspection routines to quickly and efficiently acquire data from dozens of part iterations. Users can collect sample data to . 3D scanning is the most popular 3D measurement technique for part inspection. It has become an essential tool for quality control procedures in many industries due to its versatility, accuracy, and digital integration.3D scanning for CNC services involve inviting our 3D scanning experts to your facility with our expensive equipment. We take full 3D scans of your existing parts, generate a point cloud, . In this article, we’ll discuss the different methods of metrology used for part inspection and how 3D scanning parts for CNC machining can be beneficial for quality assurance, quality control, and tooling inspection.

Does it make sense to use a 3D Scanner to inspect CNC machined parts? Typically these parts are hand measured or inspected on a CMM. Is using a 3D Scanner,.The portable 3D scanners offer real-time verification of part assembly, ensuring correct installations and reducing production errors. This guarantees that the final product functions as designed, enhancing reliability.

With 30 years of successful 3D laser scanning projects around the globe, Laser Design can help with your reverse engineering and inspection needs. We can scan, model, and inspect parts of all sizes and complexity. Laser Design’s metrology lab remains open to quote projects and receive parts for 3D scanning services. What is 3D Scanning?3D scanning uses lasers or structured light to digitally recreate a part’s surface in a non-contact, non-destructive way. This is beneficial for the maintenance and overhaul parts because it provides you with an exact replica of the part you need to replace. 3D scanning for inspection has elevated the quality control process by offering more dependable measurements, plug-and-play functionality, and unmatched speed. How do you 3D scan for CNC machined parts? What is the process of creating files ready for machine programming? The 3D scanning process is performed by 3D laser scanners that range in accuracy.

3D scanners can be used to create semi-automated inspection routines to quickly and efficiently acquire data from dozens of part iterations. Users can collect sample data to make informed choices about their manufacturing processes.

3D scanning is the most popular 3D measurement technique for part inspection. It has become an essential tool for quality control procedures in many industries due to its versatility, accuracy, and digital integration.

3D scanning for CNC services involve inviting our 3D scanning experts to your facility with our expensive equipment. We take full 3D scans of your existing parts, generate a point cloud, convert that into a high-quality 3D CAD file, and then go through quality checks and improvements to ensure the file is perfect. In this article, we’ll discuss the different methods of metrology used for part inspection and how 3D scanning parts for CNC machining can be beneficial for quality assurance, quality control, and tooling inspection.Does it make sense to use a 3D Scanner to inspect CNC machined parts? Typically these parts are hand measured or inspected on a CMM. Is using a 3D Scanner,.

3d scanning software

The portable 3D scanners offer real-time verification of part assembly, ensuring correct installations and reducing production errors. This guarantees that the final product functions as designed, enhancing reliability.With 30 years of successful 3D laser scanning projects around the globe, Laser Design can help with your reverse engineering and inspection needs. We can scan, model, and inspect parts of all sizes and complexity. Laser Design’s metrology lab remains open to quote projects and receive parts for 3D scanning services. What is 3D Scanning?

3D scanning uses lasers or structured light to digitally recreate a part’s surface in a non-contact, non-destructive way. This is beneficial for the maintenance and overhaul parts because it provides you with an exact replica of the part you need to replace. 3D scanning for inspection has elevated the quality control process by offering more dependable measurements, plug-and-play functionality, and unmatched speed. How do you 3D scan for CNC machined parts? What is the process of creating files ready for machine programming? The 3D scanning process is performed by 3D laser scanners that range in accuracy. 3D scanners can be used to create semi-automated inspection routines to quickly and efficiently acquire data from dozens of part iterations. Users can collect sample data to make informed choices about their manufacturing processes.

3D scanning is the most popular 3D measurement technique for part inspection. It has become an essential tool for quality control procedures in many industries due to its versatility, accuracy, and digital integration.

3d inspection software

3d inspection scanner

PanZone® NEMA 4X/IP66 Rated Wireless Access Point Enclosures † NEMA 4X and IP66 rating protects against corrosion, windblown dust and rain, splashing water and hose-directed water .

3d scanning parts for cnc maching part inspection|scantech for 3d inspection