where can i get sheet metal cut It can take a small, square bite out of sheet metal. We would drill holes, then use the nibbler to connect the holes and square up the edges of the resulting opening. Slightly tedious, but fine if you don't need too many or large openings. . Make sure to get a bit for cutting metal. Only thing to really think about with this is the radius of . Wiring an L5-30 receptacle: To wire an L5-30 receptacle, follow these steps: Turn off the power to the circuit at the main electrical panel. Remove the cover plate from the receptacle box. Connect the hot wires to the gold screws on the L5-30 receptacle.

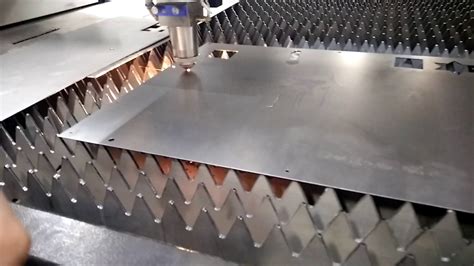

0 · wholesale sheet metal laser cutting

1 · wholesale sheet metal laser cutter

2 · precision metal cutting near me

3 · metal sheet fabrication near me

4 · local laser cutting shop

5 · laser cutting sheet metal factories

6 · custom sheet metal near me

7 · custom cut metal near me

Secure brackets and other accessories to T-slotted rails. Join T-slotted rail surfaces and corners to build virtually any structure. Connect tubes, switches, casters, and other components to T-slotted rails. Route wire, cable, and tubing along T-slotted rails. Fasten through equally spaced holes to build and adjust guards, tables, and racks.

It can take a small, square bite out of sheet metal. We would drill holes, then use the nibbler to connect the holes and square up the edges of the resulting opening. Slightly tedious, but fine if you don't need too many or large openings. . Make sure to get a bit for cutting metal. Only thing to really think about with this is the radius of .Metal Supermarkets offers a wide variety of metal-related processing services such as production cutting, shearing, delivery and more. Learn more about our fast and reliable services below and contact a store near you for availability. Phil shows you some quick tips and tricks on cutting thick sheet metal.⏱️⏱️Chapters⏱️⏱️00:00 Follow along with a handyman00:25 Cutting the metal for the vall.Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! . or Cut to Size; Select a Size 0.00. Weight: 1.00 lb/ft. Add To Cart. S122 22 GA. (.030" thick) Cold Rolled Steel Sheet A1008. S122 .

Top 10 Best Metal Cutting in San Antonio, TX - November 2024 - Yelp - CNC Cutting Services, JB Machine, Wanderlust Ironworks, Westbrook Metals, True Steel Welding And Construction, Alamo Iron Works, Eureka Sheet Metal, Brieger Welding, PR Welding and Machine Shop, M & M Metals

I also was leaning towards the sheet metal part as it automatically generates the bounding box dimensions. So all I need to get my BOM working properly is to translate the already existing sheet metal bounding box properties into the ones matched to the regular structural members so: "SW-Bounding Box Length" -> "Length"Top 10 Best Metal Cutting in San Francisco, CA - November 2024 - Yelp - Daly City Iron Works, Standard Metal Products, All Metals Welding, Bay Metals, Brothers Welding, Quasimodo Metal Works, ATR Welding, Atlas Contour, Metalmen Sheet Metal Products, RadFabs Laser Cutting A metal cut-off disc or a diamond blade disc is suitable for cutting metal rebar, steel bars, stainless steel, cast iron, and angle iron. Can you cut sheet metal with a Dremel? Yes, you can use a Dremel metal cut-off wheel to cut most metals. Refer to the packaging of the specific Dremel cut-off wheel to see its capabilities. Any basic cut-off wheel that can handle metal should do. How to Cut Sheet Metal with a Dremel. Now that you know that a Dremel is in fact one of the best tools to use for cutting sheet metal, we can get to providing you with a step-by-step tutorial on the matter. Let’s get to it and cut some sheet metal. Step 1: Gather Your Materials

If you are replacing consumables every sheet you have other issues. Find a hypertherm dealer in your area. Chances are they can recommend a small table as well as their products. The cut quality is not the same as laser but if you have good equipment it can be very good. We plasma cut as thin as 22ga with decent quality.You can cut sheet metal using your table saw, provided you pick a blade designed for metal. Even with the correct blade, though, it is dangerous. Make sure you cut very slowly and use proper safety gear. You can define the bend relief in the initial sheet metal model (see my screenshot) or adjust them individually as mentioned by dirk_van_der_vaart. Hope this helps. 0 Cut Metal with Your Circular Saw. It may not be an obvious choice, but fitted with the right blade, a circular saw is a great metal-cutting tool. In our test, it cut through rebar like a hot knife through butter. You can cut mild steel up to about 3/8 in. thick using a ferrous-metal-cutting blade. Be careful, though! Hot metal chips will fly .

cnc machining chattanooga tn

We can bring your concept to reality. We can even help with the design. Do you need a replacement for a part that is no longer available? We can help you. . Billet Metal Craft. 377 Coral St, Santa Cruz, California 95060, United States. 831-421-9601 [email protected]. Hours. Open today. 09:00 am – 05:00 pm. Drop us a line! Drop us a .Metal Sheets at Tractor Supply Co. Buy online, free in-store pickup. Shop today! . Hillman SteelWorks 12 in. x 24 in. #26 Solid Steel Sheet, Zinc-Plated. 0 (0) | Item # 352107199. Pickup Today. FREE. Same Day Delivery. Standard Delivery .99. Add to cart. Compare.Any sort of saw or grinder with a cutoff wheel will cut sheet metal. Use a square and scribe or sharpie to mark out your shapes, and my opinion would be to cut a tad bigger and file it down. Filing will be tiresome but easier to do for cheap. You can also use a dremel to cut and sand the edges with the right attachments.

Tape the sheet metal and secure it in place. Apply masking tape to both sides of the sheet metal directly over the line you want to make. This ensures a cleaner cut and prevents metal chips from scratching the sheet . Step 2 Mark The Cutting Area: Get the metal sheet to start the procedure. The very first task is to mark the targeted area. Get the marker and compass. Mark the round shape to have a round hole. Step 3 Choose The Best Cutter: Choose the best tool for making holes on the metal sheet. Have a look at the last paragraph.430 stainless steel sheet #4 finish is the brushed finish commonly seen on kitchen appliances and backsplashes. 430 Stainless Steel Sheet #4 finish has a PVC film on one side to help protect against scratching during fabrication and installation. Our 430 stainless steel sheet metal meets the criteria for both the #3 and #4 finish.

The tool I would use is metal cutting scissors (or Snips).It's remarkably easy to get a straight cut with these after a little practice. I would first make a cut far from the line (somewhere in the area you're going to discard), to get a feeling .

Try our cut-to-size metal cutting service today and experience the difference! * Please note that custom cuts on some lower price items are subject to a minimum price-per-piece . The minimum price-per-piece is £0.50 on length profiles and £1 on sheets. FAQs. What is metals4U's cut-to-length metal cutting service?Steel, aluminum, and stainless steel can all be cut in almost any size or shape with minimal heat markings or distortion. Laster cutting tolerance = +/- 1/32’’ . Get your custom cut metal from South Austin Metals today! Contact Info. 10704 South I 35 Frontage Rd, Austin, TX 78748 (512) 448-9067 [email protected] Company. About Us;Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! SendCutSend. . Standard laser cutting orders are out the door in 2-4 days. Expect 1-3 day shipping anywhere in the USA. It starts with a file. Upload a CAD file, send us a sketch, or use one of our templates. .I'd go with the jigsaw with a good metal cutting blade. The blades for that are far cheaper than a metal cutting blade for a table saw. Use a piece of angle iron, or a nice straight piece of wood as a guide fence, and you should get a clean, straight cut. .

If you cut with the aviation snips you'll notice this: 1. Straight cut (yellow handles) will "push" the metal on one side up, the other side down. 2. Left and Right cut (read or green, don't know right off which is which) will only "push" the cut metal up on one side (the left or right) and the other side will remain straight. Now that we know that an angle grinder can be used to cut sheet metal, let’s figure out exactly how to complete this task. Step 1: Prepare the Angle Grinder. Before you can get started with this task, you will need to purchase and attach a special metal cutting disc to the unit. If you don’t know how to remove and attach components on your . A skilsaw with a non-ferrous cutting blade. Usually a 40 tooth carbide blade, made for metal cutting. No oil, clean clean cuts, and you can cut way faster than with any other tool for that job. The blades are sometimes available at Home depot, etc. Usually I get them at my hardwood lumber shop/ Ganahl lumber out here.

wholesale sheet metal laser cutting

wholesale sheet metal laser cutter

cnc machining companies in arizona

Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

where can i get sheet metal cut|precision metal cutting near me